Home > Company Introduction

Company Overview

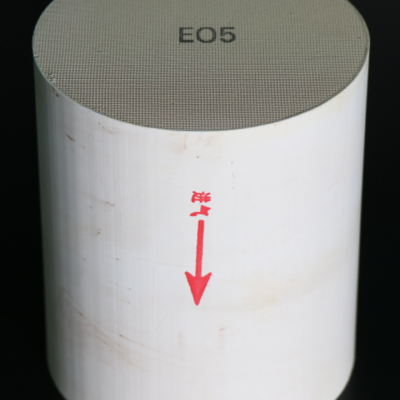

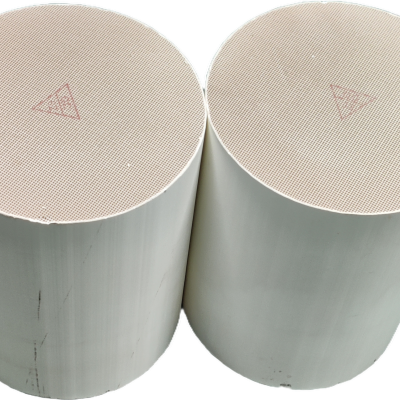

JHM Hi-Tech Nanjing Corporation, 39 Qiande Rd, Jiangning Science Park, Nanjing, China 211122. established in 2005, is a Taiwanese.founded enterprise, covering a construction area of 12,500m2, with an annual production capacity of around 8 million pcs. We are a specialized manufacturer of automotive three-way catalytic converters. Our product range includes automotive three-way catalytic converters, motorcycle exhaust purifiers, diesel vehicle exhaust purification catalysts, V-SCR, Fe-SCR, Cu-SCR, and other products. Our company complies with various mainstream standard certifications, including ISO14001, IATF16949, ISO45001,etc. With over twenty years of production experience, we serve numerous clients in regions such as China, Japan, Italy, and the United States.

-

ManufacturerBusiness Type

-

2005Year Established

-

10,000-30,000 square metersFactory Size

-

Below US$1 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

51 - 100 People Total Employees

-

1-10 People Sales Staff

-

5-10 People Quality Inspectors

-

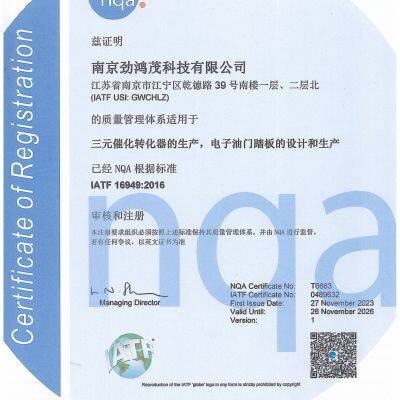

ISO14000, ISO16949, Others Product Certifications

-

Below US$1 Million Annual Export Value

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

Shanghai, Guangzhou, Ningbo, Qingdao Port of Shipment

-

Exhaust System Main Industry

-

Quality ControlThe company has always placed great emphasis on product quality control. The quality management system complies with the requirements of IATF 16949:2016 certification and develops and produces products that meet the emission regulations of various countries. Through years of research and development, the mature products now include automotive three-way catalytic converters that meet the Euro 5 and Euro 6 emission standards, motorcycle catalytic converters that meet the Euro 5 emission standards, and engine catalysts that meet the emission standards of the US EPA and Japan. During the inspection of raw materials, production process, and finished products, professional quality inspectors conduct random tests, and a product traceability system has been established. During communication with customers and suppliers, feedback information on product performance and quality is collected, and the R&D department analyzes, verifies, and makes improvements again.

Quality ControlThe company has always placed great emphasis on product quality control. The quality management system complies with the requirements of IATF 16949:2016 certification and develops and produces products that meet the emission regulations of various countries. Through years of research and development, the mature products now include automotive three-way catalytic converters that meet the Euro 5 and Euro 6 emission standards, motorcycle catalytic converters that meet the Euro 5 emission standards, and engine catalysts that meet the emission standards of the US EPA and Japan. During the inspection of raw materials, production process, and finished products, professional quality inspectors conduct random tests, and a product traceability system has been established. During communication with customers and suppliers, feedback information on product performance and quality is collected, and the R&D department analyzes, verifies, and makes improvements again. -

Our ServicesWe are a specialized manufacturer of automotive three-way catalytic converters, namely Nanjing JHM Technology Co., Ltd. Our product range includes automotive three-way catalytic converters, motorcycle exhaust purifiers, diesel vehicle exhaust purification catalysts, V-SCR, Fe-SCR, Cu-SCR, and other products. Our company complies with various mainstream standard certifications, including ISO14001, IATF16949, ISO45001. With over twenty years of production experience, we serve numerous clients in regions such as China, Japan, Italy, and the United States.

Our ServicesWe are a specialized manufacturer of automotive three-way catalytic converters, namely Nanjing JHM Technology Co., Ltd. Our product range includes automotive three-way catalytic converters, motorcycle exhaust purifiers, diesel vehicle exhaust purification catalysts, V-SCR, Fe-SCR, Cu-SCR, and other products. Our company complies with various mainstream standard certifications, including ISO14001, IATF16949, ISO45001. With over twenty years of production experience, we serve numerous clients in regions such as China, Japan, Italy, and the United States. -

Company HistoryEstablished in Jiangning High-tech Park, Nanjing City in 2005, the company has been engaged in the research and development and production of metal carriers/catalytic converters and other engine exhaust system products since its establishment. In 2013, it began to be involved in the research and development of automotive parts products. Currently, it holds over 60 national certified patents and 4 copyrights. The company strictly requires the care and protection of its employees. It conducts annual occupational health check-ups and occupational safety training for employees to ensure safety and health in the working environment and process. It has always implemented a 40-hour workweek. It implements a flat management system for departments such as R&D, production, business, quality control, and logistics, and attaches great importance to communication and exchange between employees and company managers. The company's employees have high job satisfaction and low turnover, with an average tenure of more than 10 years.

Company HistoryEstablished in Jiangning High-tech Park, Nanjing City in 2005, the company has been engaged in the research and development and production of metal carriers/catalytic converters and other engine exhaust system products since its establishment. In 2013, it began to be involved in the research and development of automotive parts products. Currently, it holds over 60 national certified patents and 4 copyrights. The company strictly requires the care and protection of its employees. It conducts annual occupational health check-ups and occupational safety training for employees to ensure safety and health in the working environment and process. It has always implemented a 40-hour workweek. It implements a flat management system for departments such as R&D, production, business, quality control, and logistics, and attaches great importance to communication and exchange between employees and company managers. The company's employees have high job satisfaction and low turnover, with an average tenure of more than 10 years. -

Our TeamThe members of the company's board of directors and the general manager have many years of experience in investment management of technology enterprises. 1. The research and development team led by an experienced doctor has over ten years of experience in the research and development of engine exhaust purification products. 2. The production team is composed of experienced technical workers with an average of over ten years of working experience, ensuring the consistency and stability of the products, with an annual production capacity of over 2 million liters. 3. The business marketing team is good at meeting customer demands and meeting the requirements of customer orders as well as quality and cost needs. 4. The quality assurance department has experienced quality control departments, internal auditors of the system, safety officers and occupational health administrators.

Our TeamThe members of the company's board of directors and the general manager have many years of experience in investment management of technology enterprises. 1. The research and development team led by an experienced doctor has over ten years of experience in the research and development of engine exhaust purification products. 2. The production team is composed of experienced technical workers with an average of over ten years of working experience, ensuring the consistency and stability of the products, with an annual production capacity of over 2 million liters. 3. The business marketing team is good at meeting customer demands and meeting the requirements of customer orders as well as quality and cost needs. 4. The quality assurance department has experienced quality control departments, internal auditors of the system, safety officers and occupational health administrators.

Our Certifications

Showcasing our professional qualifications and recognized industry certifications.